Capabilities

Our Services

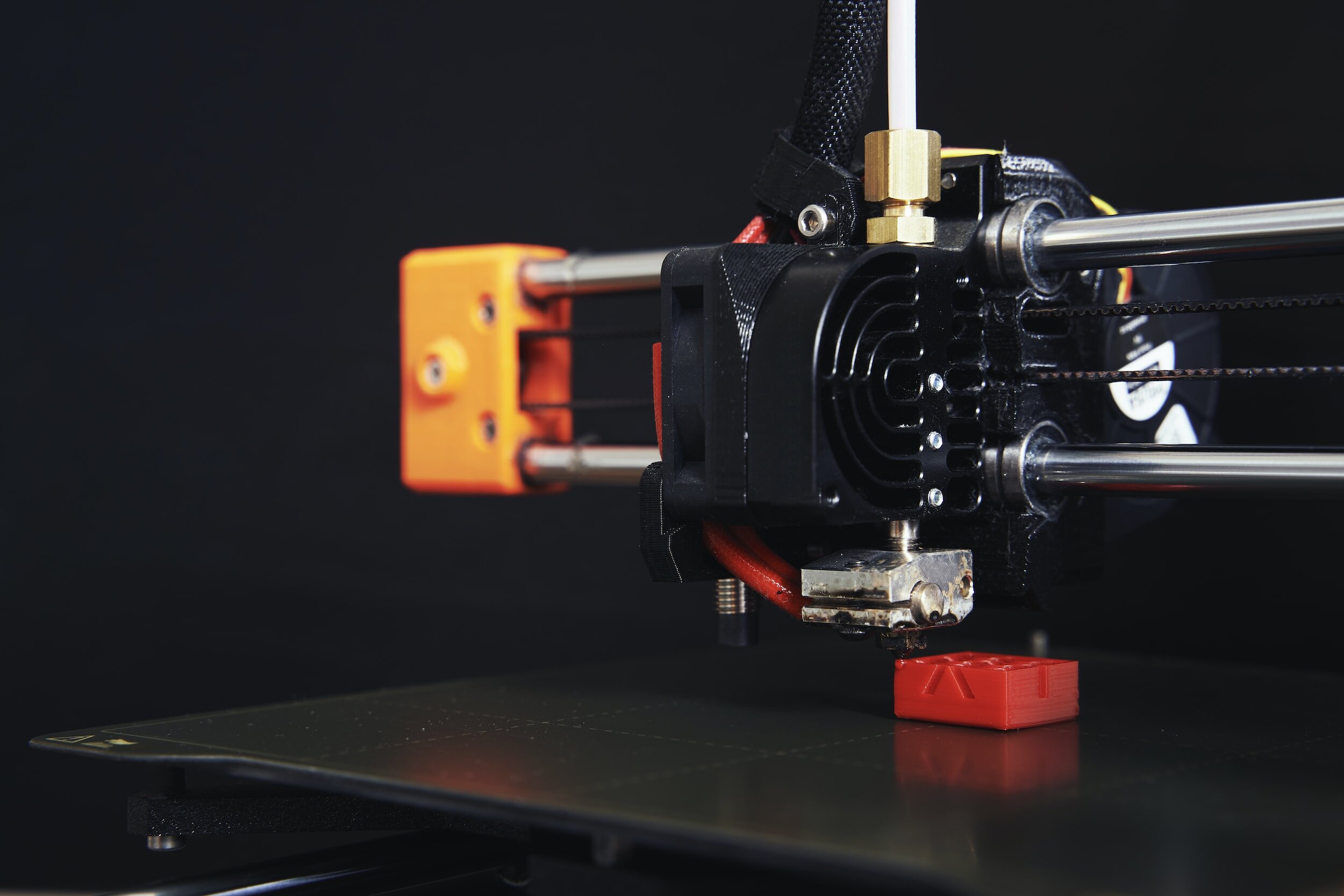

-

Description mm [in]

Max part size(LxWxH): 220 x 220 x 250 [8.6 x 8.6 x 9.8]

Minimum Feature Size: 0.4 [0.016]

Minimum Wall Thickness: 0.4 [0.016]

Minimum Feature clearance: 0.2 [0.008]

Resolution: 0.2 [0.008]

Dimensional Accuracy: +/- 0.2 [0.008]

-

Need a design or to a copy of part you have? We can do that!

Let us know your ideas and we can generate the 3D models for 3D printing, machining, CNC, laser cut, sheet metal, you name it!

-

Need a second set of eyes on a design? Not sure if your part is right for 3D Printing? Need to optimize for a process? We can work with you to make sure your part performs like you want from material selection to design features.

-

Have a mesh file you need modified before you print it? We can make the changes you need and make sure your parts fit your applications.

-

Have a logo, decal or another image that you want to hold solid in your hands? Let’s start a conversation and see how we can help!

3D Printing Materials

PLA

-

Polylactic Acid

Made from plants, PLA parts exhibit a great combination of dimensional accuracy and rigidity while remaining economical for projects.

Available in many colors and perfect as-is or sanding ready for prime, paint and other finishing processes.

-

Prototyping

Aesthetics pieces

Costumes / Cosplay

Low-stress load pieces

Low-heat environment pieces

PLA+

-

Polylactic Acid + Additives

PLA+ utilizes extra additive components which can add several effects to your parts depending upon your needs.

Silk varieties exhibit a smoother, shiny surface and boast a degree of added hardness.

Pro iterations hones mechanical properties where added strength can make or break a design.Purpose blends such as Dual/Tri color, Cosplay friendly materials and more help you find the PLA you need.

-

Prototyping

Aesthetics pieces

Costumes / Cosplay

Low-stress load pieces

Low-heat environment pieces

PETG

-

Polyethylene Terephthalate Glycol

Perfect for projects that need more chemical resistance or will be placed in warmer environments such as vehicles in the summer.

PETG parts can exhibit variable flexibility depending upon how thin or a feature is, but can also be very rigid for thicker/solid builds. -

Chemically harsh environments

Water-tight potential

Living hinges/light flexing pieces

Low/Moderate stress loads

Warmer environments

TPU

-

Thermoplastic Polyurethane

A chemically resistant plastic often mistaken for a rubber due its leather-like flexibility.

Available in many colors and perfect as-is. Not typically suited for finishing processes such as sanding or painting

-

Prototyping

Flexible Parts

Gasketing

Chemically demanding environments

Low-heat environment pieces

CARBON FIBER NYLON (CFPA)

-

Carbon Fiber Polyamide (Nylon)

Boasting superior strength, rigidity and dimensional accuracy, CFPA is perfect for demanding environments where a higher heat resistance is required.

Chopped Carbon Fiber strands reinforce designs while giving a matte finish which helps hide layer lines.

-

Prototyping

Automotive

Light-weight high strength

Medium-stress load pieces

Medium-heat environment pieces